Extruders

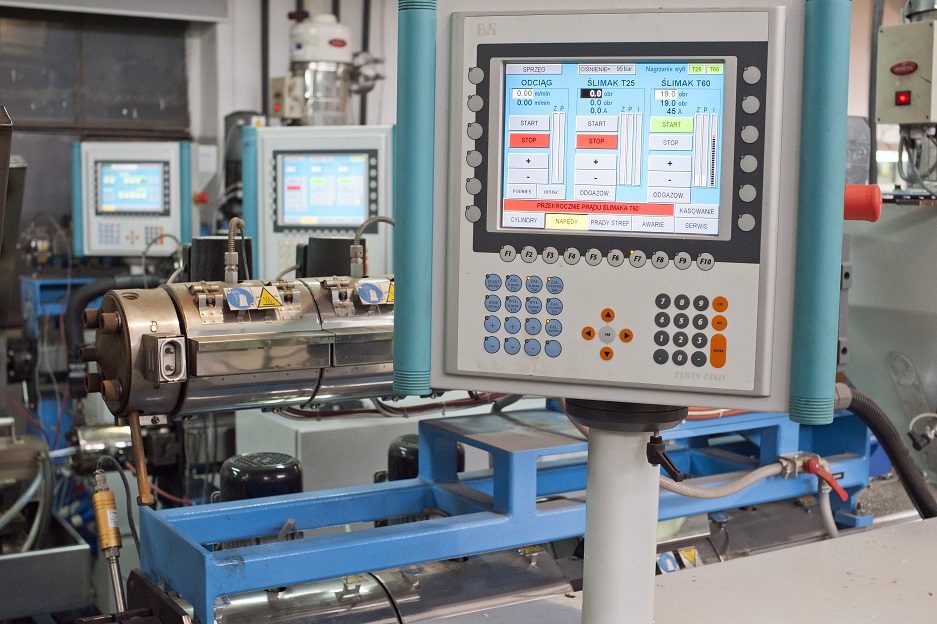

The extrusion department is equipped with 11 production lines for manufacturing plastic profiles and strips. These are fully automated lines produced by Metalchem and Greiner.

The extruders are fitted with screws of 45–60 mm in diameter and have a throughput of 30–40 kg/h. Profile and strip calibration is carried out on vacuum calibration tables equipped with vacuum pump systems.

The materials processed include: PVC, ABS, PS, TPE, PP with filler, HDPE, MABS, and PMMA.

These materials enable the production of soft–hard profiles for various industrial applications.

The use of cutting saws and punching tools allows for precise shaping, cutting, and trimming of profiles.

The department can handle custom profile designs throughout the entire production cycle — from concept and design to the final product.